⚙️ Mechanical Engineering Resources:

We have put a dozen guides for mechanical engineering students and early professionals on our website

50 Hardware Startups who have raised less than $50 million (perfect internship targets)

How to handle The Behavioral Interview

What it takes to be The 10X Intern

🙋♂️ Interview Practice Question of the Week

Company: Cover

Which is stronger, the screw or the nail?

✅ The Answer

This question is incredibly vague. That’s intentional. To answer this question, you need to first ask questions.

Primarily, what direction and type of load is it? How do the nail and screw size to each other? As always, when you ask this question, the most likely answer is: “Explain for each.”

Firstly, let’s handle the loading. There are two main types of loading we’re going to consider: tensile and shear. For tensile loading, the usual calculation is:

Stress = Force / Area

So a higher area = a lower stress. From a purely theoretical perspective, this might be correct. Most of the time though, nails and screws are used in wood. As such, let’s assume we are using this screw/nail to connect two blocks of wood. Now, we must check our assumptions. In most tensile loading questions, there is an underlying assumption that both ends are rigidly held onto (i.e. there is no slippage). This is true for one end of the nail (its head rigidly makes contact with the block, preventing any further ingress. The other end of the nail though, lacks the same feature, meaning it can be pulled back out of the block if friction is overcome.

In short, if Ftensile > Ffriction of block 2, then block one and block two will be pulled apart, regardless of the diameter of the nail/screw.

A screw on the other hand, uses threads. So long as the tension-generated radial force due to helix angle of the screw threads does not exceed Ffriction, the screw will not rotate (a frictionless screw would rotate back out and be equally as useless as a frictionless nail). As such, any tensile forces on the two blocks are not limited by friction, but rather by the strength of the wood, strength of the screw, and thread type of the screw. Deeper threads will increase engagement with the wood, meaning that the wood has a higher shear area to resist tensile loading. Stronger wood will have the same effect.

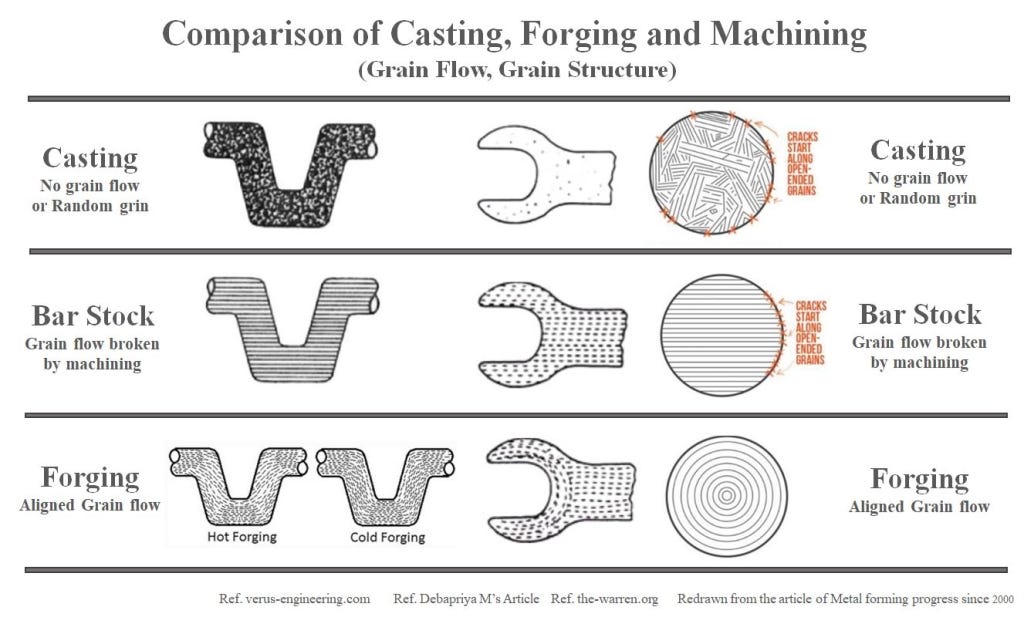

An additional failure mode to consider, is that the screw could snap between the blocks, allowing them to separate. Some semi-common knowledge that could be useful to bring up here is the difference between cast and forged components. Forged components are significantly less brittle and tougher than their cast counterparts due to adjusted grain structure and lower porosity. For this reason, forged fasteners are often used in load critical applications.

An article well worth the read is NASA’s Investigation of SpaceX’s CRS-7 Launch. The problem boils down to using cast rod ends instead of forged ones, which broke under vibrational loading (at low temperatures) 139 seconds into the flight causing the COPV (think big carbon fiber balloon held under water) to shoot up into the tank and rapidly deconstruct the rocket in less than a second. Reading the report, it appears that the manufacturer suggested a factor of safety > 4 for using the cast rod ends. This should give you a good idea about the structural inconsistency of some cast components.

🚀 Hestus - CAD Copilot

Reclaim your design time. Hestus is the AI copilot for Autodesk Fusion that eliminates the most tedious parts of your workflow. Instead of manually applying dozens of obvious sketch constraints or dimensions, Hestus proactively suggests them for you. Spend less time on digital housekeeping and more time solving the complex problems you love.

Watch the demo and try Sketch Helper for free at www.hestus.co.

Share with us how you’re using it in your designs — the first 10 entries snag a $50 Amazon Gift Card!

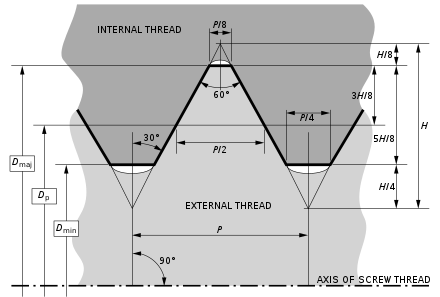

For shear loading, what we care the most about is the cross sectional area of the nail / screw. It is very important to note that the cross sectional area of the screw we must consider is the minor diameter. This is the narrowest diameter of the screw, and where failure will occur. It could also be argued that a screw will better resist shear for this particular application of binding two blocks together, as the friction between the two blocks will ideally play a role (this is actually how bolts work, and it’s very interesting — hopefully we will release more on that later). That would however be slightly dependent on if one of the blocks was predrilled at greater than the major diameter. More generally though, the problem of shear loading performance can be answered by checking the minor diameter of the screw vs. the minor diameter of the nail and seeing which one is larger.

Note: the designing of bolts is an underappreciated art. There are all sorts of standards dictating every part of a screw for different purposes. One of the most striking ones (and my personal favorite) that we rarely think about, is the small flat portion on the inside of the threads that helps prevent crack propagation.

Torsional loading doesn’t really need to be discussed in this use case, as the system is under constrained without a second point of attachment (which would almost always be added). By adding a second point of attachment, the torsion turns into two cases of shear!

The summary regarding which is stronger: a nail or a screw? As with pretty much anything, it depends! Primarily on the use case. Hopefully this response has helped you with the tools to analyze any use case you are given.

Now when it comes to practical knowledge, there are some general rules of thumb. For example, nails tend to be less expensive than screws so, for things that require buckets and buckets of them like roofing or framing, nails are probably the better option. They are also quicker to install so good for keeping UPH (units per hour) up. Screws are best for cabinetry (unless you got a brad nailer) and flooring because both things see lots of loading and you don’t want squeaky floors or loose cabinets.

Also, DO NOT FORGET to pre-drill your holes. Otherwise, you may crack your wood. It’s a tedious step but nothing worse than finding a crack in your wood just when you thought you were done.

Thanks for reading! Have something interesting (and hardware related) YOU want to write about? Drop us a line at hardwareishard@gmail.com!