What is Onshape?

Onshape is a browser-based CAD software that integrates a Google Docs-like collaboration/version control interface with a classic CAD modeling environment.

It is absolutely phenomenal. We used it for every project we did in college and continue to use it on a weekly basis for side projects!

It’s intuitive, simple, and things exist where they should. Plus, new features and improvements are always coming out!

Onshape was created by Jon Hirschtick after he left SolidWorks (the most popular CAD software in the world), a company he had founded 17 years prior.

Why did he decide to start from scratch?

Design teams now live in a spread-out world and need a platform that lets them collaborate across time zones, tech stacks, and even languages.

In a mobile-cloud-first world, people work via laptops, not old desktop PCs, and CAD should adapt to that.

As avid users, we think Jon and his team absolutely killed it!

Why Is Onshape The CAD Of The Future? → CAD In A Post COVID World

We love to look at data, and Google Trends is one of our favorite places to explore.

SolidWorks is the most popular software in the world due to its extensive educational efforts over the last couple of decades. Students receive SolidWorks for free in school, and then when they enter the real world, they want to use SolidWorks. It's that simple.

Onshape is following that exact same customer acquisition strategy, and COVID really accelerated it.

Look at the massive spike in interest in August/September of 2020.

Students went back to school remotely, and teachers wanted them to use/learn CAD. Not everyone has a PC desktop at home, so SolidWorks wasn't an option.

Interest skyrocketed for a cloud/web-browser native CAD software with real-time collaboration capabilities. It has been trending upward ever since.

The above data reflects relative interest, but on an absolute basis, the story remains consistent. SolidWorks' interest has generally remained stable, with a slight downward trend, whereas Onshape's growth is steadily increasing, with peaks correlating to the school year. The strategy is indeed working!

I believe that the majority of this interest lies within middle school and high school levels. However, as this generation of kids transitions into early-career mechanical engineers, they will likely prefer Onshape.

If you’re reading this, the odds are that you’re a ~ college-age mechanical engineering student, so let's explain why it is also the best software to use on campus for class projects!

Why Is Onshape The Best Choice For Projects?

One File, One Project

The story is consistently the same.

A four-person team project is divided into 10+ parts, with each member responsible for designing 2-3 parts. One student prefers Fusion360, two have access to Solidworks, and the final member insists on using Inventor. About 3-4 weeks into the semester, they encounter a problem.

How can the students consolidate all the files into one assembly? Should they use Solidworks? Do all the STEP files use the same units?

Even if everyone initially uses SolidWorks, setting up PDM is not a practical option. GrabCAD somewhat works but is cumbersome.

Oh, and to make things worse, not all the parts actually fit together. Everyone based their models on a few dimensions and some screenshots shared in the group chat, resulting in collisions. It's a chaotic situation. There are no viable solutions.

We have written a comprehensive article (how to build an A+ project) explaining why Onshape is the best choice for such projects (coming out next week). Here's a basic summary:

Onshape allows all team members to work in the same file, using different tabs for various parts and one central assembly. Everyone can view all components at all times, eliminating the risk of overwriting someone else's work.

And, in case something goes wrong, guess what? You can roll back in the revision history, just like in a Google Doc, on a click-by-click basis. It's truly remarkable!!!

Onshape is also lightweight, so if someone is using a Chromebook or a Mac (the premiere CAD laptop 🤣), they can work on the project without late-night trips to the computer lab.

It's also extremely easy to learn, so if you have team members who don't have a ton of CAD experience, that's totally fine. They should be able to get up to speed in days, not months.

Sign up for a FREE educational account here and get started right now.

Break out those calipers and CAD the cup on your desk. Take Onshape for a spin!

For Companies

Price

I was first introduced to Onshape when a startup I interned at was using it. Initially, I was extremely frustrated because it felt unnecessary to learn yet another CAD software, but I quickly became a convert.

Speaking of startups . . . Onshape does the craziest thing. They offer startups 1 year of free CAD. They understand you might be cash-strapped when getting started and want to grow with you!

Not working at a startup???

Onshape’s Discover Program gives you 6 months of free CAD if you sign up with your work email.

You should mention one/both of these programs to your managers at your next job/internship. Onshape is always growing and adding new features and your manager/CEO might not know about the new programs!

As an employee of a large company, you don't realize how expensive CAD software is.

There is the sticker price per user ($4,000-$8,000).

There is the Product Data Management (PDM) software cost per user (~$2,000).

Finally, there are the installation/maintenance/server costs ($5,000-$20,000+).

This doesn't even include the cost of dedicated high-performance CAD computers for every engineer.

IT ALL ADDS UP

Onshape's pricing is simple: $2,500 a year for CAD software that includes built-in PDM, runs in the cloud (managed by Onshape), and can be used on any laptop (PC, Mac, Chromebook).

PDM

Unfortunately, every company treats part numbers, revisions, releases, etc. differently. The common thread is that it is a real pain.

Now, this may be a little out of left field, but software engineers have a much better system. They use a branch/merge structure that enables parallel development while code is running live.

Us, hardware engineers usually just copy and paste stuff into a new part number.

Look out for our dive into Onshape's branch/merge capabilities in the future!

Analytics

One other unique feature of Onshape is that they track everything, and the data is accessible! For example, you could see that 60% of total CAD time is going to project A, 25% to project B, and 15% to project C.

Furthermore, you can track how much modeling time each individual engineer on your team is spending per day/week/month and by project. This can be especially helpful if you use CAD contractors and want to hold them accountable.

Favorite Features

We have already written 1,000 words about how much we love Onshape, and we haven't even talked about the actual CAD work.

We could easily make this article 6,000 words long with all the features we love.

Instead, we will be dedicating a section in some HWH newsletters to walk you through our favorite features!

Let’s kick it off! Here’s our first tip!

⚙️Onshape Tip - Laser Cut Finger Joints

One of the most versatile machines in a college makerspace is the Laser Cutter.

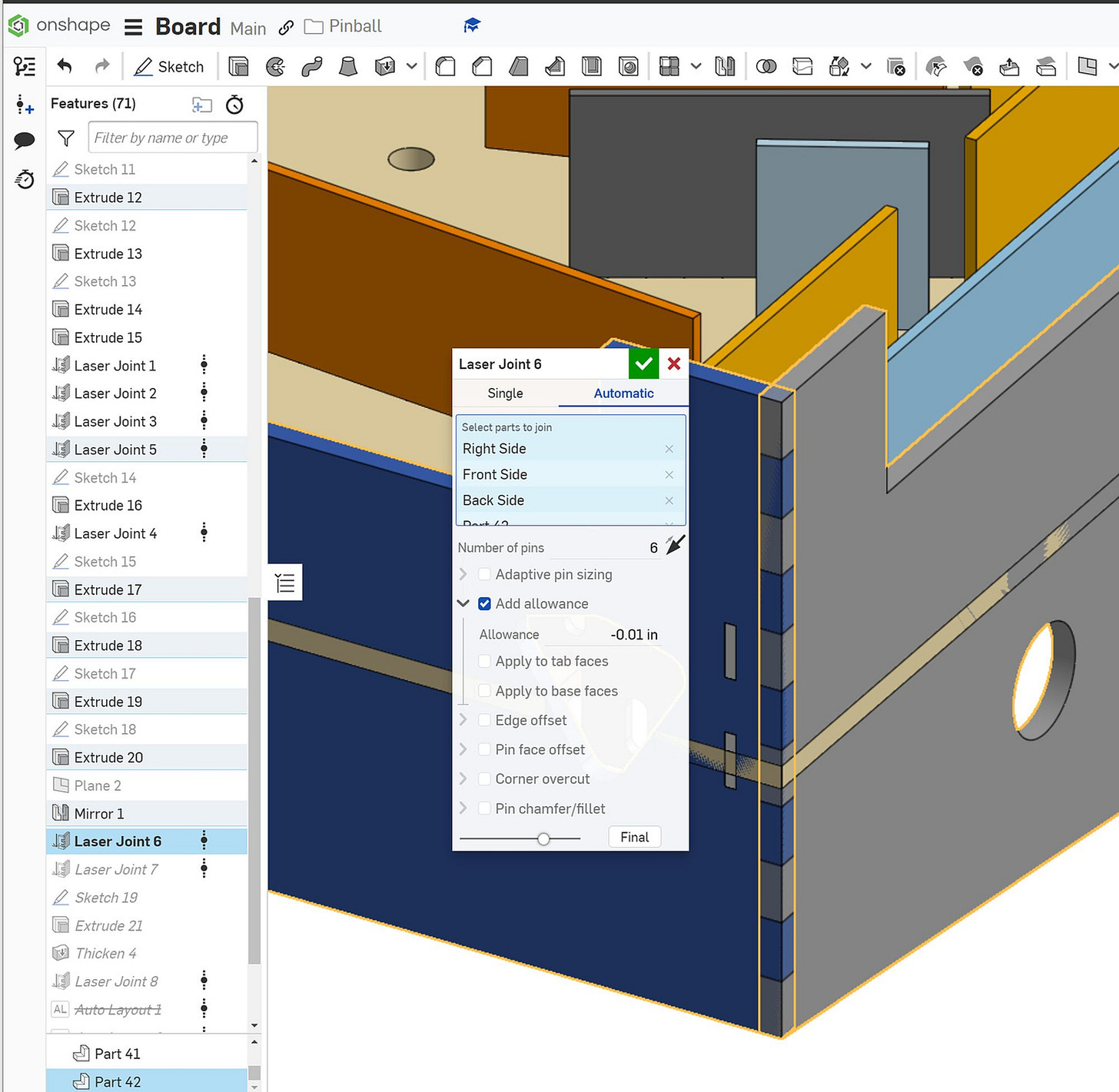

It enables you to build things larger than a 3D print build plate 10x faster than you could any other way. The secret is to weave 2D cut geometries into 3D parts. The best way to do this is by creating finger joints to increase the gluing surface area (the wood is usually too thin to screw together without splitting it).

Most makerspace helpers will point you to a fingered box site like this. But what if you don't want to make a simple box? What if you have higher aspirations? For your sake, we hope you do.

Well, in Solidworks, your main option involves drawing an absurd number of lines and offsetting them. Odds are, you'll make a mistake and have to start over. Although it's a rite of passage to experience this frustration at least once, it's also a significant waste of materials, money, and time. Trust us when we say there are 101 better ways you can and will waste your time when it comes to projects.

Born from the depths of this struggle is one of our favorite Onshape features: the Laser Joint tool."

Take any two parts you want to have a finger joint, make sure they’re the same thickness, and have them intersect. Then open the feature script, select the two parts, and BOOM you have a laser joint. Play with the number of pins to maximize engagement but minimize cut time and you’re off to the races!

Quick tip: provide negative 10 thou of offset to compensate for the burned wood (kerf) that is removed. Note that every laser cutter is different so you may want to do some small-scale tests of this value to tune it to whatever laser cutter you’re using.

~WAIT~ is that an auto-layout tool I see used as well? Tune in next month for how to minimize your time in DXF-land and Illustrator!

What are you waiting for?

Great article! I still use SolidWorks (perhaps unfortunately) but your article has me thinking that my club should consider a transition to OnShape. One note/correction, GrabCAD is what a lot of university engineering teams used to use (specifically GrabCAD Workbench), but that service has been shut down as of June 2023 and can no longer be used as a substitute for PDM, making OnShape an even more attractive option.